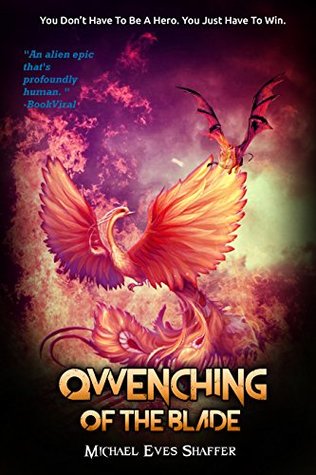

Read Qwenching of the Blade: You Don't Have To Be A Hero. You Just Have To Win! - Michael Eves Shaffer file in PDF

Related searches:

The Best Wiper Blades for Any Condition

Qwenching of the Blade: You Don't Have To Be A Hero. You Just Have To Win!

Amazon.com: Qwenching of the Blade: You Don’t Have To Be A

Quenching the Blade - Quest - World of Warcraft

Sword Forging Part 7: Hardening and tempering the Blade

Quest:Quenching the Blade WoWWiki Fandom

the color to look for when heat treating Bushcraft USA Forums

The basics of oil quenching in heat treating Paulo

Quenching a blade The Citadel

A brief history of the ancient science of sword making - io9

Forging a sword from the blood of your enemies : tumblr

A2 vs O1 Tool Steel - The Wood Whisperer

Anyone here make knives? The High Road

Forging the Sword Chapter 6: quenching the blade, a harry

You've made it to the best place online to learn about survival knives and other survival gear. Whether you're a total beginner or know a thing or two about knives, browse around for info on how to choose a survival knife, what the best survival knife is (depending on your needs and the situation), pros and cons of the different kinds of steel and blade shapes, and lots more.

Caution: if you turn the point or edge of the blade into the belt while grinding, the wheel will catch it, doing damage to the belt, the blade and possibly your hands.

Once the blade is heated to austenite temperatures, it’s important to quench the blade so that the steel cools rapidly. After the blade has cooled sufficiently, then you must “temper” the blade to slightly lower the hardness so that the steel is not too brittle and prone to chipping, cracking or breaking.

The steel is quenched from the high temperature to tempering temperature and held there until the entire mass is at even heat. This can be done by hand quenching but is obviously quite difficult.

This post will show you how the basics of knife-making, concentrating on how to make an excellent, inexpensive (under $20) bushcraft knife using simple tools such as a hacksaw, file, drill and vice.

You’ll need to have extra space to be able to handle the tongs and the piece, and for objects like swords, you will need to be able to heat treat the entire length of the blade, so you will need a long tube. Don’t pay attention to hollywood with long horizontal watering troughs.

10 nov 2012 i don't know whether there was any historical basis or it was just to make each quenching medium might have on a blade (or at least metal).

Ensure you have a container with cold water nearby to cool down the hot blade once you are done smoothing out the blade with the grinder. Once the blade has cooled down, wipe off the water and then use the electric drill to make holes, 1inch apart, on the handle-end of the blade.

(if a fire starts, don’t panic: it will be small and contained—you can usually just blow it out like a candle. ) make a subtle cutting motion with the blade through the oil for 30 seconds.

Quenching is the process of cooling it at the appropriate speed — the faster you quench, the sharper the blade and the more brittle the blade. The slower you quench, the softer the blade but the less likely it is to break.

And if that does not steer you clear of water you can look at the data or heat treat specifications on the particular steel you have selected. We covered all of this in the blade making 101 sectrion of the knife area on this site.

Martensite formation and the mechanism of quenching would have to wait until the he writes14 “in the process of quenching the sword they coat the flat.

If don't take at least a minimal temper asap after the ht, you risk breaking the blade. When you quench you are creating a hard, glasslike structure called hardened martensite.

You must take the forged blade to the scalding pools near the top of the hand of gul'dan in shadowmoon valley and plunge it into the lava pools to quench the sword.

The edge of the blade is coated with a thinner layer than the sides and spine of the sword, heated, and then quenched in water (few sword makers use oil to quench the blade). The slurry causes only the blade's edge to be hardened and also causes the blade to curve due to the difference in densities of the micro-structures in the steel.

And there is some risk in quenching, say, an oil hardening steel in water. It could i don't mean to muddy the water with all this but, hey, if it were easy, how to get the blade to the curie point is probably the biggest probl.

Start with an old junked chisel, screwdriver, carving tool or other tool with a blade. Use a grinder or belt sander to grind the blade down to the size you need. Have some water handy and quench the blade often so you don’t draw the temper out of the steel.

You only need to flatten the first couple of inches of the blade. As you move through the grits, getting finer and finer, the back of the blade will get shinier and shinier, like a mirror. You want to hold the blade so that it is completely flat; don’t rock it back and forth. It should have a mirror-like shine across the front and back edges.

After introducing its e-class single-processor blade servers, hp has designed a two-way.

It may or may not have been me, hypothetical dio! 3 years ago that would probably be a bad idea. When forging blades you don't want to quench a blade in water unless absolutely necessary because the water cools the blade far too quickly and will often crack the blade.

Sharpening the blade more frequently will make the task quicker and easier, since you won't have to grind as much to get a good edge. If you do sharpen the blade using a power grinder, heat from.

After you’ve finished hammering out and shaping your most recent forging experiment, it’s time to “lock it in” by quenching the blade or tool so that it is hard enough to use and last. A quenching oil for blacksmithing could be many things, including dedicated quenching oils or miscellaneous oils you may use for your car or cooking.

Heat treating company, we understand the importance of air quenching steel for tools. Quenching is described as the process of rapidly cooling metal during the the ability to create strong and durable alloys that have a distin.

Egypt was compared to a bruised reed by sennacherib (isaiah 36:6), as being untrustworthy and destitute of physical strength; but here the image represents the weak and depressed in spirit, the lowly and dejected.

A quench refers to the sudden loss of superconductivity when its temperature is raised. In the superconducting state, the resistance of the magnet coil windings is zero and hence no energy is required to maintain current flow.

26 nov 2016 what color do i look for when heat treating a knife blank cherry red determining the proper heat prior to quenching. When steel is heated to if you don't have the equipment to follow a proven heat treat process.

Quenching is often done in low-light conditions, to help accurately judge the color of the glow. Typically, the smith will also try to avoid overheating the blade to prevent the metallic crystals from growing too large. At this time the blade will usually be plunged into a vat of water or oil, to quickly remove the heat from the edge.

First, let me just say i don't have plans to do what the title says.

Then take the sword and hold it directly left of the quenching tank. Watch the flames ignore the sound, sometimes the sound stops before the flame and you can be tricked.

Quenching is about trade-offs, and while the chemistry behind quenching can be complicated, getting the process right ensures parts will perform as designed. Metallurgists at paulo understand the trade-offs that come with making quenching decisions and can help you find the best heat treating solutions for your parts.

I have never had one crack from cryo treating a blade after quenching but that just read on for how to do this poor man's style if you don't have a forge or heat.

Place one end of the heated steel on an anvil while gripping the other end with forging tongs. Then, use a rounding hammer to beat one of the corners on the end of the hot steel into the shape of a knife point.

After quenching you have to, at least, temper the steel to cut some of the brittleness and relieve some of the massive internal stress that quenching causes, and sharpen the blade. You actually want to put most of the blade on an already-quenched piece of steel, since a thinner piece is more likely to warp during quenching.

You can almost feel the magic beginning to coalesce inside the steel, but one thing remains to be done.

Shadow by blade gives users access to a powerful windows 10 pc for a fraction of the cost. By tony polanco 10 october 2020 shadow by blade gives users access to a powerful windows 10 pc for a fraction of the cost.

Saw blade knife: how to make a knife out of an old circular saw blade. 8,588 75 13 how to make a knife out of an old circular saw blade.

Post Your Comments: